1Postgraduate Student, Department of Prosthodontics, Nair Hospital

Dental College, Mumbai, Maharashtra, India

2HOD and Professor, Department of Prosthodontics, Nair Hospital

Dental College, Mumbai, Maharashtra, India

3Department of Prosthodontics, Nair Hospital Dental

College, Mumbai, Maharashtra, India

Corresponding Author Email: hemabalach123@gmail.com

Article Publishing History

Received: 25/07/2025

Accepted After Revision: 16/09/2025

Gypsum products are widely used as die materials in prosthodontics owing to their ease of use, accuracy, and cost-effectiveness. However, they are prone to surface abrasion, which may compromise the marginal integrity of restorations. Application of surface hardeners has been proposed to enhance abrasion resistance, though results in the literature remain inconsistent. To compare the abrasion resistance of two type IV die materials, Ultrabase and Pearlstone, with and without the application of three different die hardeners under controlled laboratory conditions. A total of 112 specimens were prepared using standardized carbon steel dies. The specimens were divided into eight groups (n=14 each): Ultrabase and Pearlstone uncoated (controls), and each material coated with Maarc, MDM, or 2GM die hardener. Abrasion resistance was tested using a custom-designed abrasion machine under loads of 20 g and 50 g. Mean weight loss was calculated before and after abrasion.

Data were statistically analyzed using ANOVA, Kruskal–Wallis, and independent t-tests, with significance set at p<0.05. Uncoated specimens exhibited the highest mean weight loss, while all surface hardeners significantly reduced abrasion. At 20 g load, Pearlstone with Maarc coating showed the least weight loss. At 50 g load, Pearlstone coated with MDM demonstrated the greatest resistance. Overall, Pearlstone performed better than Ultrabase irrespective of the hardener used. Pooled analysis confirmed significantly lower mean weight loss in coated specimens compared to controls (p≤0.001). Surface hardeners enhance the abrasion resistance of type IV gypsum dies, with Pearlstone showing superior performance over Ultrabase. Incorporation of surface coatings may improve the durability and accuracy of working dies in prosthodontic practice.

Die materials; Gypsum; Abrasion resistance; Surface hardeners.

Bala H. P, Kharsan V, Basar N, Chougule P & Shamkule R. Comparative Evaluation of Abrasion Resistance of Two Type IV Die Materials with Three Different Die Hardening Agents: An In Vitro Study. International Journal of Biomedical Research Science (IJBRS). 2025;01(3).

Bala H. P, Kharsan V, Basar N, Chougule P & Shamkule R. Comparative Evaluation of Abrasion Resistance of Two Type IV Die Materials with Three Different Die Hardening Agents: An In Vitro Study. International Journal of Biomedical Research Science (IJBRS). 2025;01(3).. International Journal of Biomedical Research Science (IJBRS). 2025;01(3). Available from: <a href=”https://shorturl.at/rl4lU“>https://shorturl.at/rl4lU</a>

INTRODUCTION

Gypsum products are among the most frequently employed materials in prosthodontics for the fabrication of definitive casts and dies [1]. Their popularity stems from their ease of manipulation, cost-effectiveness, compatibility with various impression systems, and controlled setting expansion [1,2]. These characteristics make them highly suitable for producing accurate reproductions of oral structures and facilitating successful indirect restorative procedures [3]. Despite these advantages, gypsum products exhibit several inherent limitations, such as low fracture strength, dimensional instability, technique sensitivity, and most importantly, susceptibility to abrasion [4]. These shortcomings may compromise the marginal fidelity of restorations and ultimately affect their clinical longevity.

Surface abrasion is a significant concern in laboratory procedures. Repeated manipulations such as carving, finishing, or disinfection of gypsum dies can accelerate surface wear [5]. Marginal abrasion in particular may jeopardize the accuracy of fixed prostheses. Several approaches have been explored to improve the abrasion resistance of gypsum dies [6]. Epoxy resin has shown superior mechanical strength compared to gypsum-based materials; however, its use remains limited due to high cost and dimensional inaccuracy [7]. Other approaches, such as altering the mixing liquid with colloidal silica or soluble resin, have improved strength but introduced undesirable changes in setting expansion [8].

A more widely accepted method involves application of surface hardeners, including cyanoacrylate resins, colloidal silica, and commercial protective coatings. Fukui et al. demonstrated that cyanoacrylate coatings could improve surface hardness by forming a thin protective film, while Richardson highlighted the importance of maintaining optimal film thickness [9]. Lindquist et al. showed that abrasion resistance and water sorption were influenced by the specific combination of die material and hardener [10]. Similarly, Harris and associates observed that hardener coatings altered surface hardness, although results varied depending on the base material [11].

Given the growing availability of commercial surface hardeners and the inconsistencies reported in previous investigations, further comparative evaluation is necessary. The present in vitro study was designed to compare the abrasion resistance of two type IV die materials, UltraBase and Pearlstone, with and without the application of three different die hardening agents, in order to provide reliable evidence for clinical and laboratory practice.

MATERIAL AND METHODS

Study Design: The present in vitro experimental study was conducted at the Department of Prosthodontics in collaboration with the Indian Institute of Technology, Bombay. The study protocol was approved by the institutional ethical review board (IEC-NHDC Project No:- EC-202/PROSTHO/ND13/2023, dated: 25/07/2023)

Materials Used: Two ADA type IV gypsum die materials were selected for the study: K Ultrabase and Pearlstone. Three die hardeners were chosen based on their clinical availability and widespread use: Maarc die hardener (Shiva Products Ltd., India), MDM die hardener, and 2GM die hardener. Uncoated specimens of both die stones served as control groups. All materials were procured from a single batch to eliminate batch-related variability.

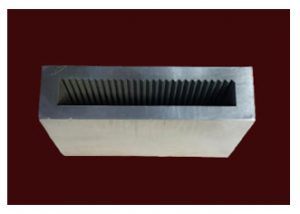

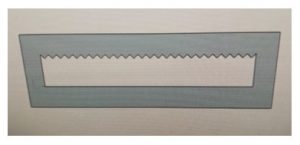

Preparation of Specimens: A standardized carbon steel alloy die was fabricated with dimensions of 50 × 50 × 8 mm, containing 27 vertical ridges of 1 mm depth, each with an internal and external slope of 45° (Figure 1). These ridges were designed to simulate the margins of a prepared tooth (Figure 2). Impressions of the die were made using a putty-wash technique and evaluated for surface imperfections. The die stones were mixed according to the manufacturer’s instructions: distilled water was first placed in a vacuum mixing bowl, the powder added gradually, soaked for a few seconds, hand spatulated for 10 seconds, and subsequently mixed under vacuum for 20 seconds.

Figure 1: Carbon steel alloy dyes used to fabricate samples in the study.

Figure 2: Ridges incorporated in the design of the dies.

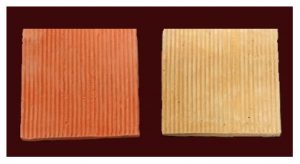

The slurry was carefully incrementally poured into the impressions while placed on a mechanical vibrator set at 6000 cycles/min and 0.4 mm amplitude, to prevent entrapment of air bubbles. The filled metal moulds were placed on a glass slab to ensure a parallel base. After allowing the specimens to set for 1 hour at an ambient temperature of 20 ± 2 °C and relative humidity of 50 ± 10%, the casts were retrieved. A total of 112 specimens were prepared, 14 for each subgroup (Figure 3). All specimens were stored at 24–26 °C for 14 days to ensure complete drying.

Figure 3: Prepared specimens

Grouping of Specimens: The prepared specimens were divided into eight groups of 14 samples each:

- Group 1A: Ultrabase, uncoated (control)

- Group 1B: Pearlstone, uncoated (control)

- Group 2A: Ultrabase + Maarc die hardener

- Group 2B: Ultrabase + MDM die hardener

- Group 2C: Ultrabase + 2GM die hardener

- Group 3A: Pearlstone + Maarc die hardener

- Group 3B: Pearlstone + MDM die hardener

- Group 3C: Pearlstone + 2GM die hardener

Each group was further subdivided for abrasion testing under 20 g and 50 g loads.

Application of Die Hardeners: For the experimental groups, the respective die-hardener was applied uniformly to the surface of each specimen with a fine camel hair brush. Excess material was allowed to evaporate according to the manufacturer’s guidelines. The control groups received no surface coating.

Abrasion Resistance Testing: Abrasion resistance was evaluated using a custom-designed abrasion testing machine based on the recommendations of Lindquist et al. The stylus of the machine was passed repeatedly across the ridges of each specimen under controlled load conditions. Weight loss of each specimen was recorded before and after abrasion using a precision electronic balance, and the difference was expressed in milligrams as an indicator of abrasion resistance.

Statistical Analysis: All collected data were entered into Microsoft Excel spreadsheets and analyzed using SPSS statistical software (version 23, IBM Corp., USA). Descriptive statistics, including mean and standard deviation, were computed for each group. Normality of data distribution was assessed using the Shapiro–Wilk test. Depending on the distribution, comparisons among multiple groups were performed using one-way ANOVA with post-hoc Tukey’s test for normally distributed data, or the Kruskal–Wallis test for non-parametric data. For paired group comparisons, the independent samples t-test or Mann–Whitney U test was employed as appropriate. A p-value of <0.05 was considered statistically significant.

RESULTS

Descriptive Statistics under 20 g Load: A total of 112 specimens were evaluated for abrasion resistance, divided equally between two die materials (Ultrabase and Pearlstone) with and without the application of three different die hardeners. The initial analysis focused on weight loss recorded under a 20 g load. The mean weight loss values for each group are presented in Table 1.

Uncoated specimens demonstrated the highest weight loss in both die materials, indicating greater susceptibility to abrasion. In contrast, application of die hardeners consistently reduced the mean weight loss. Among the Ultrabase groups, the lowest value was observed with 2GM die hardener (1.26 mg), followed closely by Maarc (1.36 mg) and MDM (1.41 mg). For Pearlstone, the lowest mean weight loss was seen with Maarc (0.79 mg), while MDM and 2GM also demonstrated reduced values compared with the uncoated control.

Table 1. Mean weight loss (mg) of specimens under 20 g load

| Die Material | Uncoated | Maarc Hardener | MDM Hardener | 2GM Hardener |

| Ultrabase | 2.24 | 1.36 | 1.41 | 1.26 |

| Pearlstone | 2.01 | 0.79 | 0.99 | 1.19 |

Overall, Pearlstone specimens exhibited lower mean weight loss compared to Ultrabase across all groups. The greatest reduction in abrasion was noted in Pearlstone coated with Maarc hardener, suggesting superior performance of this combination under a lighter load.

Descriptive Statistics under 50 g Load: When specimens were subjected to a 50 g load, all groups showed increased weight loss compared to their counterparts tested at 20 g. The mean values are summarized in Table 2. For Ultrabase specimens, the uncoated control exhibited the highest mean weight loss (2.94 mg). Application of die hardeners significantly reduced weight loss, with Maarc (1.60 mg) and 2GM (1.64 mg) demonstrating better performance than MDM (1.86 mg).

Similarly, Pearlstone specimens showed a substantial reduction in abrasion with surface hardeners compared to the uncoated control (2.98 mg). Among these, MDM produced the lowest mean weight loss (0.90 mg), followed closely by Maarc (0.96 mg), while 2GM showed slightly higher values (1.66 mg).

Table 2. Mean weight loss (mg) of specimens under 50 g load

| Die Material | Uncoated | Maarc Hardener | MDM Hardener | 2GM Hardener |

| Ultrabase | 2.94 | 1.60 | 1.86 | 1.64 |

| Pearlstone | 2.98 | 0.96 | 0.90 | 1.66 |

On inter-material comparison, Pearlstone once again demonstrated lower weight loss values than Ultrabase when coated with hardeners, particularly in the MDM and Maarc groups. The findings reaffirm the protective effect of surface hardeners under higher load conditions, with Pearlstone showing a more favorable response compared to Ultrabase.

Comparative Statistical Analysis: Statistical testing revealed that within the 20 g load groups, the reduction in weight loss was significant for MDM-coated Ultrabase specimens compared to the uncoated control, whereas no significant difference was detected in the 2GM and Maarc subgroups. For Pearlstone, the application of Maarc hardener produced the most significant reduction in abrasion values.

At the 50 g load, significant improvement in abrasion resistance was observed in 2GM-coated specimens compared to controls, while differences among the other hardeners varied depending on the die material tested. Inter-material comparisons indicated that Pearlstone consistently exhibited lower weight loss values than Ultrabase irrespective of the type of surface treatment, and this finding was statistically significant (p = 0.006).

When pooled data of all coated groups were compared against uncoated controls, specimens treated with die hardeners demonstrated markedly lower mean weight loss. This difference was found to be highly significant (p ≤ 0.001), confirming the overall protective effect of surface treatments on the abrasion resistance of gypsum dies.

DISCUSSION

The present study evaluated the effect of three commercially available surface hardeners on the abrasion resistance of two type IV die materials, Ultrabase and Pearlstone. Abrasion resistance was measured under two different loads, 20 g and 50 g, to simulate varying laboratory conditions that may occur during finishing, adjustment, and routine handling of dies. The findings revealed that application of surface hardeners consistently improved the abrasion resistance of both die materials, with Pearlstone exhibiting superior performance compared to Ultrabase across most experimental conditions.

The reduction in weight loss among coated specimens can be attributed to the formation of a protective surface layer that resists wear under mechanical stress [12,13]. Hardening agents such as cyanoacrylates and resin-based coatings are known to penetrate the superficial microporosities of gypsum and polymerize, forming a barrier that distributes load and minimizes fracture propagation [9,14,15]. In the present study, the differences between the three hardeners suggest that the chemical composition and penetration ability of each material play a critical role in determining effectiveness. For example, Pearlstone treated with Maarc and MDM demonstrated the least abrasion under higher loads, likely due to more uniform film formation and deeper surface penetration compared to 2GM.

These observations are consistent with earlier reports. Lyon et al. (1987) demonstrated significant differences in abrasion resistance among various die stones, emphasizing the influence of material composition [16]. Lindquist et al. (2002) found that resin-impregnated stones did not significantly differ from conventional stones in abrasion resistance but showed reduced material loss, suggesting a protective effect similar to that observed with surface coatings [17]. In a subsequent study, Lindquist et al. (2003) reported that improvements in abrasion resistance and reductions in water sorption occurred only with specific material–hardener combinations, corroborating the current findings that not all surface treatments are universally effective [10].

Harris et al. (2004) noted that die hardener coatings could paradoxically reduce surface hardness in certain gypsum products, highlighting the variability in outcomes depending on the interaction between base material and coating [11]. In contrast, He et al. (2010) demonstrated that while penetration of hardeners did not substantially alter intrinsic mechanical properties, the presence of a surface film effectively protected the die surface from abrasion damage [18]. These findings align with the present study, where the protective layer provided by hardeners significantly reduced mean weight loss compared to uncoated controls [19].

Pearlstone consistently outperformed Ultrabase in terms of abrasion resistance across different hardener groups. This may be related to its finer particle size distribution and denser microstructure, which provide a stronger base for surface coating [10,20]. Similar results were reported by Singh et al. (2018), who observed that abrasion resistance varied among different brands of type IV die materials and that certain materials exhibited superior performance when combined with specific surface hardeners [21].

The clinical implications of this study are noteworthy. Marginal accuracy of fixed prostheses depends heavily on the integrity of the working dies [22]. Surface abrasion during laboratory procedures can lead to marginal discrepancies that compromise restoration fit [23,24]. The use of surface hardeners therefore represents a practical and cost-effective method to improve the durability of dies and ensure better clinical outcomes [25]. The results of this study reinforce the recommendation that application of surface coatings should be considered routine practice in prosthodontic laboratories, especially when using type IV die stones for fabricating precision restorations.

Despite its valuable findings, this study has certain limitations. It was conducted under in vitro conditions, which may not entirely replicate the complex variables encountered in clinical and laboratory settings. Only two brands of type IV die materials and three surface hardeners were tested, which may not represent the full range of products available commercially. In addition, only short-term evaluation of abrasion resistance was performed, without assessing the long-term stability of the coatings under repeated cycles of use and disinfection. Future studies incorporating a larger variety of materials, long-term aging protocols, and different modes of mechanical testing would provide more comprehensive insights.

CONCLUSION

Within the limitations of this in vitro study, it can be concluded that the application of surface hardeners significantly improves the abrasion resistance of type IV die materials. Among the tested combinations, Pearlstone coated with Maarc and MDM die hardeners demonstrated the least weight loss, while Ultrabase specimens also benefited from surface treatment though to a lesser degree. Overall, Pearlstone exhibited superior resistance compared to Ultrabase, irrespective of the hardener used. These findings highlight the clinical relevance of employing surface hardeners to enhance the durability and accuracy of working dies, thereby improving the reliability of prosthodontic procedures.

REFERENCES

- Singh M. Gypsum & Gypsum Products: Their Science & Technology. CRC Press; 2022 Nov 17.

- Mazumder DD. A Comprehensive Review on Materials Used in Various Specialized Areas and Disciplines of Dentistry: Analyzing Their Economic Feasibility and Biocompatibility.

- Bustillo Revuelta M. Gypsum products. Construction materials: geology, production and applications. 2021 Mar 3:195-215.

- Meng T, Hu Y, Fang R, Kok J, Fu Q, Feng G. Study of fracture toughness and weakening mechanisms in gypsum interlayers in corrosive environments. Journal of Natural Gas Science and Engineering. 2015 Sep 1;26:356-66.

- Nejatian T, Firouzmanesh P, Syed AU. Dental gypsum and investments. InAdvanced Dental Biomaterials 2019 Jan 1 (pp. 37-54). Woodhead Publishing.

- Duke P, Moore BK, Haug SP, Andres CJ. Study of the physical properties of type IV gypsum, resin-containing, and epoxy die materials. The Journal of prosthetic dentistry. 2000 Apr 1;83(4):466-73.

- Wankhade S, Wankhade J, Khalikar A, Mukhopadhyay P. Comparative evaluation of fine detail reproduction of six different die materials-An in-Vitro study. International Journal of Oral Health Dentistry. 2023 Jan 18;7(3):166-71.

- He L, Liu L, Cao C, Jiang F, Xu J. Improved curing performances of epoxy resin by a structure-controllable self-emulsifying curing agent. Journal of Adhesion Science and Technology. 2022 Mar 4;36(5):490-506.

- Fukui H, Lacy AM, Jendresen MD. Effectiveness of hardening films on die stone. The Journal of prosthetic dentistry. 1980 Jul 1;44(1):57-63.

- Lindquist TJ, Stanford CM, Knox E. Influence of surface hardener on gypsum abrasion resistance and water sorption. The Journal of prosthetic dentistry. 2003 Nov 1;90(5):441-6.

- Harris PE, Hoyer S, Lindquist TJ, Stanford CM. Alterations of surface hardness with gypsum die hardeners. The Journal of prosthetic dentistry. 2004 Jul 1;92(1):35-8.

- De Brito J, Flores-Colen I. Gypsum plasters. InMaterials for Construction and Civil Engineering: Science, Processing, and Design 2014 Dec 1 (pp. 123-184). Cham: Springer International Publishing.

- Mencik J. Mechanics of components with treated or coated surfaces. Springer Science & Business Media; 2013 Mar 14.

- Campagni WV, Prince J, Defreese C. Measurement of coating agents used for surface protection of stone dies. The Journal of Prosthetic Dentistry. 1986 Apr 1;55(4):470-4.

- Ghahremannezhad HH, Mohamed SE, Stewart GP, Weinberg R. Effects of cyanoacrylates on die stone. The Journal of prosthetic dentistry. 1983 May 1;49(5):639-46.

- Lyon HE, Mitchell RJ, Patterson T. A comparison of abrasion resistance of dental stones. Dent Mater 1987;3:49-51.

- Lindquist TJ, Stanford CM, Mostafavi H, Xie XJ. Abrasion resistance of a resin-impregnated type IV gypsum in comparison to conventional products. The Journal of prosthetic dentistry. 2002 Mar 1;87(3):319-22.

- He LH, van Vuuren LJ, Planitz N, Swain MV. A micro-mechanical evaluation of the effects of die hardener on die stone. Dental materials journal. 2010;29(4):433-7.

- Smolik J. Hard protective layers on forging dies—development and applications. Coatings. 2021 Mar 24;11(4):376.

- Prithviraj DR, Khare S, Gupta A, Shruthi DP. Assessment Of The Effect Of Disinfectants And Die Hardeners On Hardness And Abrasion Resistance Value Of Type Iv Gypsum Product-An In Vitro Study. International Journal of Clinical Dentistry. 2011 Aug 1;4(3).

- Singh R. Use of Fused Deposition Modeling Assisted Investment Casting for Developing Functionally Graded Material. Book Manufacturing Techniques for Materials. 2018 Apr 9.

- Naveen YG, Patil R. Effect of the impression margin thickness on the linear accuracy of impression and stone dies: an in vitro study. The Journal of Indian Prosthodontic Society. 2013 Mar;13(1):13-8.

- Pereira GK, Pilecco RO, da Rosa LS, Machry RV, Baldi A, Scotti N, Valandro LF, Tribst JP, Kleverlaan CJ. Does the Restoration Design and Material Affect Indirect Restorations’ Marginal and Internal Gap, Interfacial Volume, and Fatigue Behavior?. European Journal of Dentistry. 2025 Mar 12.

- Al-Mussawi RM, Farid F, Haider J. Effect of Die Materials on Marginal and Internal Adaptation of Zirconia Copings: An In Vitro Study. The Open Dentistry Journal. 2021 Dec 31;15(1):708-16.

- Sawicki J, Gorecki M, Kaczmarek Ł, Gawroński Z, Dybowski K, Pietrasik R, Pawlak W. Increasing the durability of pressure dies by modern surface treatment methods. Chiang Mai Journal of Science. 2013 Jan 1;40(5):886-97.